At least 100 cases of various types of water are brought in to the technical center of DAICEN MEMBRANE-SYSTEMS, and the water treatment processes according to the needs of the customers are searched for.

Hearing about the undiluted solution and the treated water

The processes including pretreatment which are realized with the collection of technologies of DAICEN are proposed.

The technologies of separation, concentration and purification and the know-how backed up by a lot of experiences and results are our strengths.

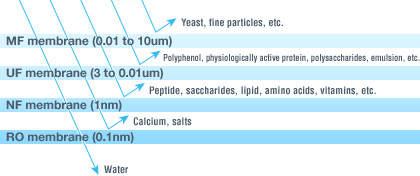

A wide variety of treatments including separation, disinfection and clarification of several nanometers to several microns is possible. Other than above, we also have electrolytic techniques and agglomeration technique techniques.

You can select the place of testing.

Our company

Our company Testing by the customer using a rental machine

Testing by the customer using a rental machine On-site testing by our dispatched personnel

On-site testing by our dispatched personnel

Selection of the optimal membrane module and necessary number of units is conducted.

In addition, rough simulation of the initial cost, the running cost and the space required for installation is performed.

A test is conducted using the actual module. The test machine can be selected from a rental machine, new installation, arrangement of the existing equipment, etc.

The following data are collected.

Engineering data

Engineering data Operating conditions

Operating conditions Tentative calculation of the cost

Tentative calculation of the cost

The equipment is designed and manufactured. Not only design, installation and instructions on operation, but also total service including the maintenance after installation are provided.

More and more sophisticated food processing processes like health food, medical and pharmaceutical products, food for the sick and processed food can be dealt with "membrane".

-

-

- Low temperature treatment is possible.

- It is possible to perform concentration during purification.

- Continuous operation is possible.

-

- High energy cost is required.

- Continuous operation is impossible because it is batch-type operation.

There is a growing need for separation technology by membrane treatment in the field of food such as concentration of food, in which necessary ingredients are lost if it is performed by heat treatment.

- Disinfection of mineral water

- Clarification of draft beer and soft drinks

- Concentration of fruit juice and dairy products

- Purification processes of the raw materials for health food and functional food

Processes in the functional food industry

Manufacturing of a processed food which uses enhanced protein by extracting and concentrating whey protein is desired.

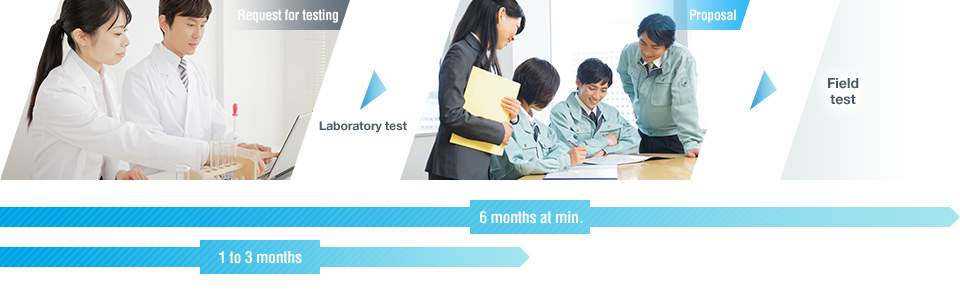

- Hearing

- Hearing about the raw material and the substances to be extracted. We will hear the conditions of production and the environment of the facility, and consider the optimal separation/ concentration method.

- Laboratory test

- After receiving the actual raw material, analysis is performed at our technical center, and proposal about the treatment processes are considered.

- Proposal

- We propose safe and high-quality extraction and concentration without breaking the ingredients by heating realized with the hollow fiber membrane module (UF membrane) manufactured and sold by our company.

- Field test

- A test is conducted using the actually used membrane module. The test is conducted under the conditions which are closer to the actual operation than the former test to collect the data.

Starting from design of the equipment, installation through instructions for operation are totally supported. We also offer consultation on maintenance after installation.

![]()

Tokyo Headquarters:

JR Shinagawa East Building 14F 2-18-1, Kounan Shinagawa-ku Tokyo 108-8230

TEL: +81 (0)3-6631-3000 / FAX: +81 (0)3-6631-3006