Solution

Processing water

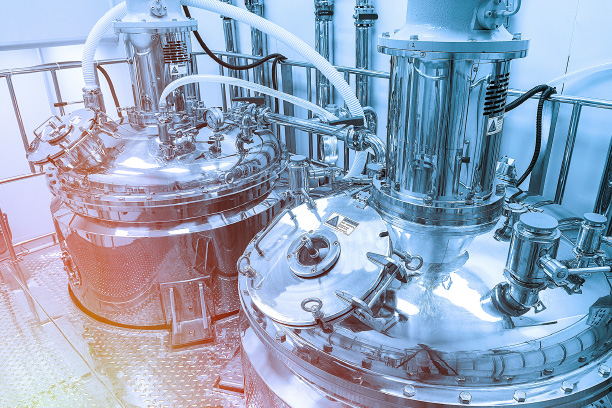

Contributing to producing of advanced pure water used in manufacturing processes

Membrane filtration technology is highly effective in advanced producing of pure water.

Producing of pure water used in manufacturing processes requires treatment with a UF or RO membranes. With our modules, advanced producing of pure water can be realized.

Processing water used at various sites and separation membranes

Processing water refers to water used in industry and manufacturing processes, mainly as cooling water, cleaning water, and water for chemical reactions and extraction. Depending on the intended use, processing water must meet specific quality requirements such as pH, hardness, content of dissolved substances, and control of microorganisms. In the general manufacturing industry, standards are left to each manufacturer.

Processing water must be appropriately treated to meet the requirements for the intended use. Specifically, appropriate treatment must be selected according to the water source and its status. Ultrafiltration membranes (UF membranes) are used for disinfection and turbidity removal of industrial water and river water for general industries and removal of bacteria, pyrogens, and endotoxins from purified water. In addition, reverse osmosis membranes (RO membranes) remove dissolved substances such as hardness components and ions. Our technology is also used for the treatment of high-quality processing water, such as purified water, pure water, and ultrapure water.

The membrane separation technology, which does not require chemicals or heating, has been chosen as a water treatment method that achieves both reliability and reduces the environmental impact.

What separation membranes can do

-

Purified water

Pyrogen-free waterUsing RO and UF membranes together to produce purified water while removing not only bacteria but also pyrogens and endotoxins.

-

Disinfection and turbidity removal of feed water

Removing turbidity and fungi contained in feed water with a UF membranes. When the module is applied to tap water, it preserves and stabilizes the water quality.

-

RO water from which hardness components have been removed

Removing hardness components and ionized substances that cause scaling with RO membranes.

Application examples in the processing water field

-

1

Processing water for production of medical raw materials

Can be used as purified water and pyrogen-free water.

- RO series

-

2

Water for the final cleaning of equipment

Can be used as purified water and pyrogen-free water.

- RO series

-

3

Culture water and extracted water for research

Can be used as purified water and pyrogen-free water.

- RO series

-

4

Processing water for food and beverage

Can be used as disinfected and clarified water.

- Hollow fiber

-

5

Processing water for chemical plants

Can be used as disinfected and clarified water or RO water from which ionized substances and hardness components have been removed.

- Hollow fiber

- Spiral

-

6

Disinfected and clarified industrial water

Can be used as disinfected and clarified water.

- Hollow fiber

-

7

Boiler water and heating water

Can be used as RO water from which ionized substances and hardness components have been removed.

- Spiral

Advantages of the separation membranes over conventional methods

-

Physical and reliable removal performance

Since this method physically removes bacteria compared to UV disinfection or chemical injection, there is no residual dead bacteria resulting in improved purified water quality.

-

Energy-saving and

sustainable treatment methodSince treatment is accomplished by simply pumping water, energy consumption is lower than that of distillation. Since the separation membranes can be cleaned and reused repeatedly, running costs may be reduced.

PRODUCTS

Water purifying apparatus RO series

Water purifying apparatus has a treatment configuration consisting of “pretreatment + RO membranes + UF membranes” packaged in one system. The RO membrane removes ionized substances and hard components. Finally, the UF membrane removes bacteria to produce water equivalent to a purified water level.*

*Pursuant to the Japanese Pharmacopoeia

All equipment required for pure water treatment packaged in one system

that reduces delivery times, costs, and labor for selection

A water purifying apparatus is generally large and designed specially for plants. However, we provide the RO series, which packages the necessary equipment in one system for small businesses, delivering efficient solutions with reduced time, effort, and cost. A variety of combinations of options can meet your water quality requirements.

Hollow fiber UF membrane module

This membrane module is suitable for the disinfection of water for beverage and food production, and for the disinfection and turbidity removal of feed water to a level comparable to tap water.

Cellulose acetate (CA) membranes are highly hydrophilic, specialized for water treatment, and widely used in various water purification plants in Japan.

Use of UF membranes based on the know-how as a membrane manufacturer

to improve both water quality and extend the service life of equipments

UF membranes are used not only to improve water quality but also to extend the service life of equipments at later stages. From the perspective of a UF membrane module manufacturer, we can offer proposals even taking operational support into account.

Cellulose acetate hollow fiber membranes

suitable for industrial water use and dedicated water supply

We recommend cellulose acetate membranes to obtain processing water equivalent to tap water level without heat disinfection. Cellulose acetate is naturally derived, resistant to contamination, and unlikely to experience a drop in performance. Thus, filtration flow rates can be maintained for a long time.

Spiral type RO membrane module

This module can remove ionized substances dissolved in water with its reverse osmosis membranes.

Based on our knowledge as a membrane manufacturer, we can offer proposals including pre- and post-treatments

We can also offer proposals not only for improving water quality by using modules but also for equipment including appropriate pre- and post-treatments.

Our strengths

-

01

High functionality

- Small variations in membrane pores and high membrane separation performance

- Extensive lineup of membrane pore and hollow fiber sizes. Compatible with various treatment applications

-

02

Not only membrane modules but also system design

- As a membrane manufacturer that has extensive knowledge on membrane treatment, we can offer comprehensive solutions for entire treatment systems